In Amsterdam, experts recently met at a PolyCE workshop to discuss how design can help increase the use of recycled plastics. There was also a debate about what designers and manufacturers expect from recycled plastics. An exciting interplay that plays a decisive role for a sustainable future.

Location: Philips Global Headquarters in Amsterdam. Time: mid-September 2019. Objective: the creation of a business case for recycled plastics. Representatives from all sectors of the electronics value chain in the EU will participate. The PolyCE workshop, entitled „Circular Design of Electrical and Electronic Equipment – the challenge of post-consumer recycled plastics“, can be summarised in a few words.

PolyCE stands for „recycled high-tech polymers for the recycling industry“. In this EU-funded project, 20 companies and organisations are working to strengthen the value chain for recycled plastics in the EU. This is urgently necessary in view of the ever-increasing quantities of plastic waste!

Exciting project partners

Important OEM manufacturers such as Philips and Whirlpool are involved in this project, as are researchers from the Fraunhofer Institute and the University of Leuven. PolyCE also involves several design houses (Pezy Group, Imagination Factory) and, of course, collection and recycling organizations for electrical and electronic waste (Ecodom, Sitraplas). And of course, the Austrian pioneer MGG Polymers is also on board for this project.

Strengthening recycling

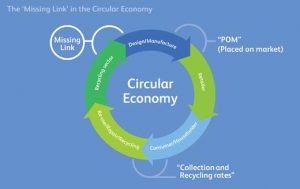

The PolyCE experts involved want to promote the use of recycled plastics in order to be able to reduce the consumption of new plastics at the same time. At present, attempts are being made to close the „missing link“ of the recycling economy. This missing link is the link between recyclers and producers of electrical appliances – in this case in the plastics sector. The project partners regularly exchange information on how electronic products can best be designed so that they can be recycled more easily and effectively. In addition, they are looking together for ways in which plastics recycled from WEEE can best be reused in new electronic equipment.

The PolyCE experts involved want to promote the use of recycled plastics in order to be able to reduce the consumption of new plastics at the same time. At present, attempts are being made to close the „missing link“ of the recycling economy. This missing link is the link between recyclers and producers of electrical appliances – in this case in the plastics sector. The project partners regularly exchange information on how electronic products can best be designed so that they can be recycled more easily and effectively. In addition, they are looking together for ways in which plastics recycled from WEEE can best be reused in new electronic equipment.

The workshop in Detail

In order to pursue these goals, more than 40 participants met at the PolyCE workshop in Amsterdam in September. They discussed concretely how post-consumer recycled (PCR) plastics from electronic scrap can be processed in applications and products that place high demands on aesthetics and material quality. In addition some Best Practice examples were taken under the magnifying glass. Arthur Schwesig of MGG Polymers showed some examples of how PCR plastics can be processed in products that are well accepted on the market. Chris Slijkhuis was the second member of the MGG family to present the company. As a representative of the European Association of Electronic Recyclers (EERA), he showed how legislation can hinder the development of a recycling economy and what measures are necessary to prevent such difficulties. As a concrete example, he cited the international disagreement on flame retardants in used plastics, which created many problems last year.

Opportunities were also identified to stimulate the market for recycled plastics. The aim is to encourage companies to use more recycled plastics in their products. In addition to timely delivery in sufficient quantities, the use of PCR plastics must always take into account that the technical properties of the materials differ as little as possible from those of virgin materials. For this reason, the exchange of experience is a decisive success factor in the various design phases.

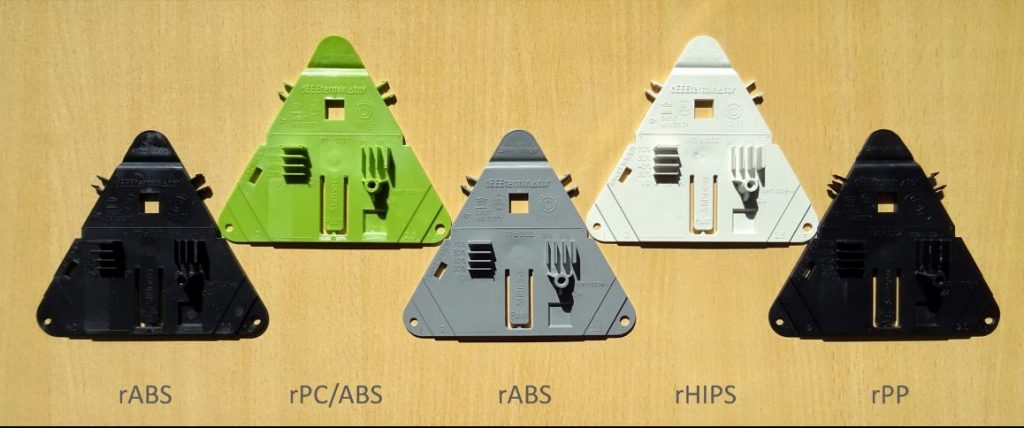

Various working groups have been working on new designs for PCR plastics. For example, the University of Ghent presented some convincing test samples of the various polymers that are currently being recycled in Europe. The representatives from Ghent pointed out many of the design decisions to be taken into account – surface properties, joining mechanisms, physical properties and so on.

Lots of potential

The workshop in Amsterdam showed the potential of design with recycled plastics for new electrical and electronic equipment (EEE). This workshop also provided convincing and economically sound arguments as to why the use of recycled plastics makes ecological and especially economic sense.

The most important finding: The hurdles for the use of PRC plastics in new high-quality electrical and electronic products can be overcome – above all with well thought-out design!